WPC extrusion production line

- Joinzeal

- Hubei China

- 35 -60days

- 300 set

1.The WPC extrusion production line is our company's main product, with experienced low-cost formulas, reasonable mechanical design, and a strong technical team.

2.The WPC extrusion production line utilizes recycled PP/PE plastics mixed with agricultural waste (such as wood chips, rice husks, straw, and wheat straw) to maximize the production of environmentally friendly building products. The wood content can reach 70%。

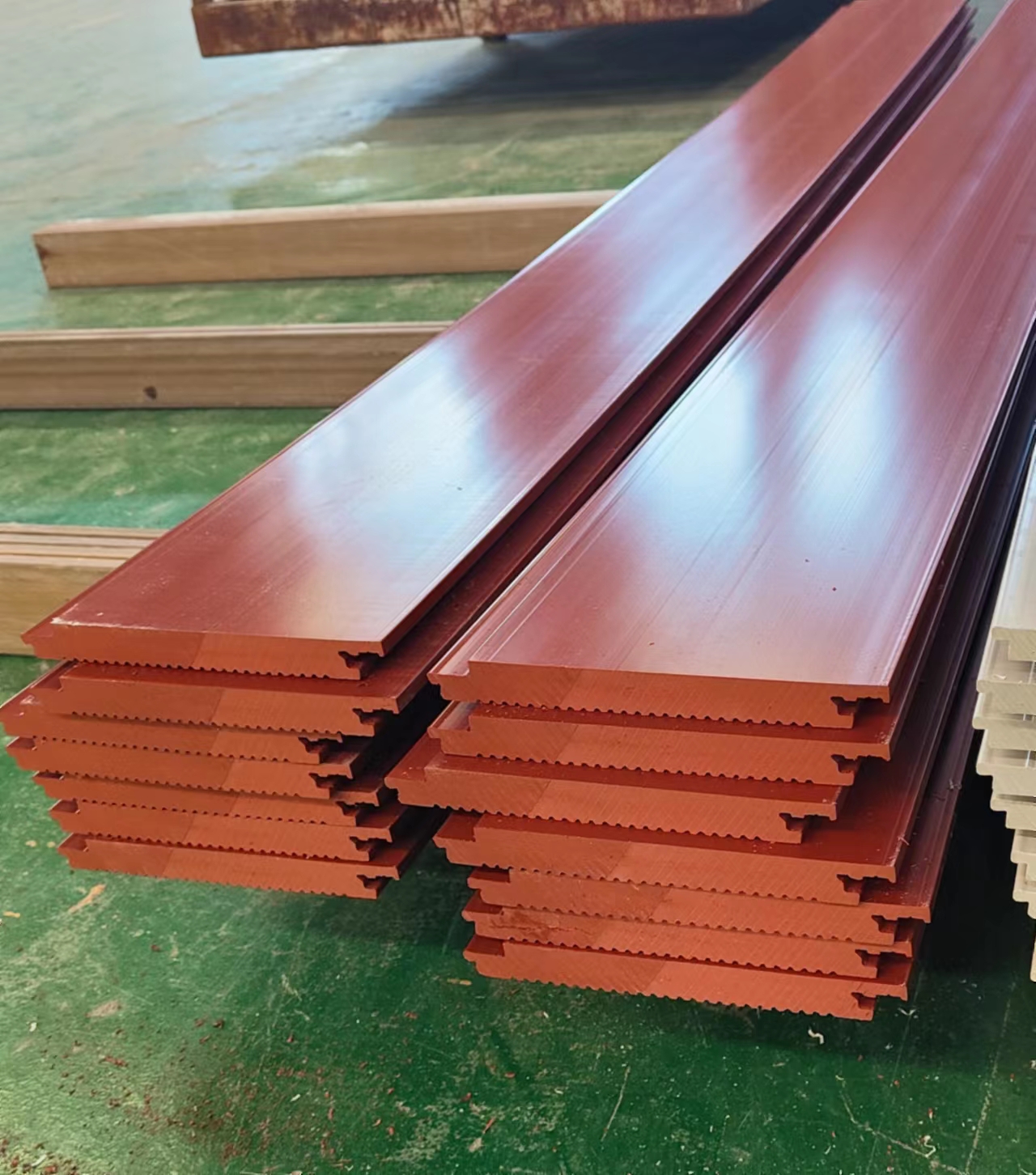

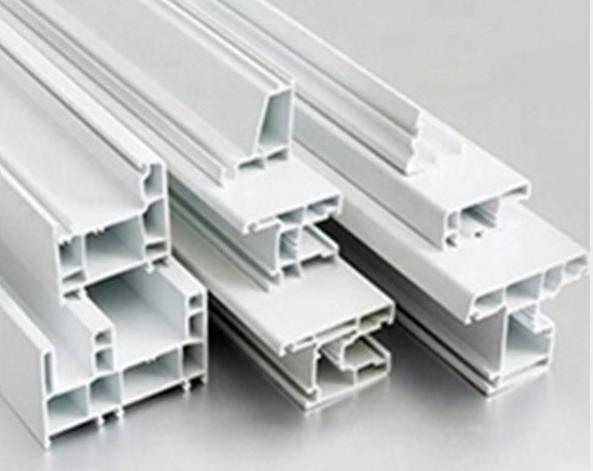

3.The wpc extrusion production line is mainly used to produce wood plastic profiles, such as wood plastic finishes, wood plastic wall panels, wood plastic fences, wood plastic pavilions, wood plastic flooring, etc

4.A WPC extrusion production line can produce different WPC products, but different WPCextrusion moulds need to be replaced, such as wpc wall panel molds, wpc floor molds, wpc ceiling molds, wpc column molds, etc

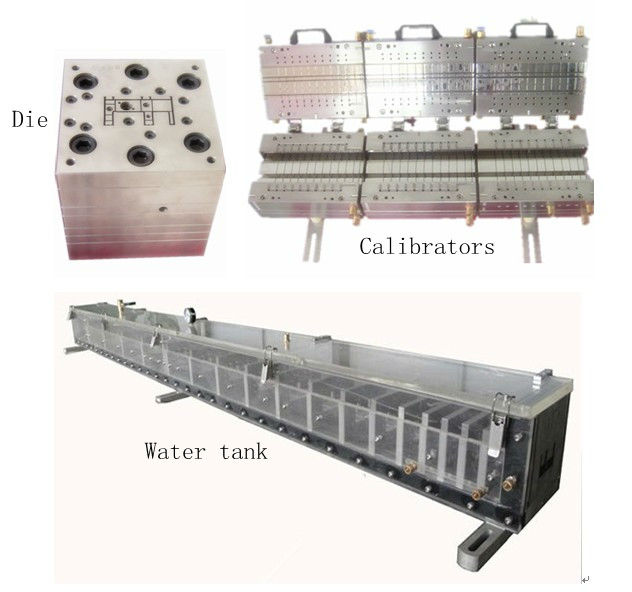

WPC mould

1) WPC moulds design is based on flow simulations on our computer, flow analysis and experience, that leads to excellent flow characteristics.

2) High precision positioning pin design guarantees accurate plate assembly

Calibrator

uses high efficient vacuum device and cooling system design to guarantee great quality of finished products and smooth profile surface

Water/vacuum tank

a) Newly designed water/vacuum tanks supply vacuum and cooling water

b) High quality materials and unique design ensures high efficient cooling and proper seal to maintain constant water and vacuum supply in the tank

c) Self adjusting templates guarantee final sizing of profile

d) Tank material available: Plexiglas or fiberglass

e) High-sealing vacuum water tank of PVC window mould adopts floating setting design, able to adjust automatically

Fine quality after-sale service:

1.Our company has high level of technology,rich experiences in testing mould or machine and good reputation service team.

2.Principles of service: First testing combined with tracking service

Orientation services linked with peripatetic service

Technical services united with training endorsement

3.Replying clients' problems in time ,and the technical can be arrived in three days.

4.One year warranty for the mould,and maintain for the whole life.

Product test results

NO. | Test Items | Technical Requirements | Units | Measured Value | Single Conclusion |

1 | Extrusion speed | 0.8-1.8 | m/min | 0.87 | conform |

2 | Yield | >98 | % | 99 | conform |

3 | Thickness deviation | <1.2 | mm | 0.24 | conform |

4 | Water absorption | ≤3.0 | % | 1.0 | conform |

5 | Density | ≥0.85 | g/ cm³ | 1.38 | conform |

6 | Tightness | No leakage | / | conform |

Product line:

Mould composition:

Our export mould :

If you are interested in our moulds, please feel free to contact with us and show us your sample picture or drawings.We will do our best to provide you with competitive price and professional service!