3cr17 WPC Wood grain Extrusion Plastic Molding

- zhongjie

- Huangshi

- 30-45Days

- 100sets per month

1. 11 years professional experience

2. One year warranty

3. High extrusion speed

4. Provide complete set of production process and technology transfer service .

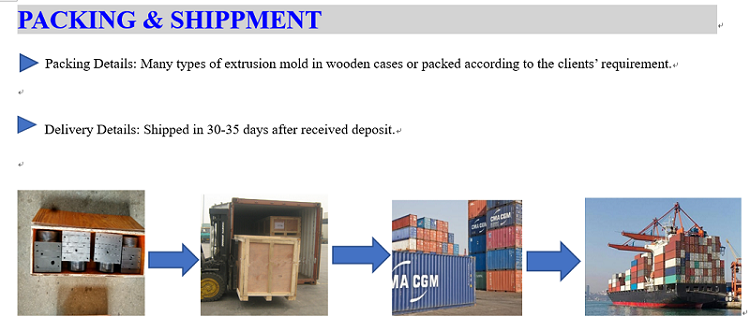

5. Wooden package

6. Hotselling all over the world

7. Used for the indoor and outdoor decoration

3cr17 WPC Wood grain Extrusion Plastic Molding

Name | 3cr17 WPC Wood grain Extrusion Plastic Molding |

Mould material |

3Cr17, 3Cr17MoNiV, DIN2316 or as per your request |

Mould cavity | One or multi-cavity |

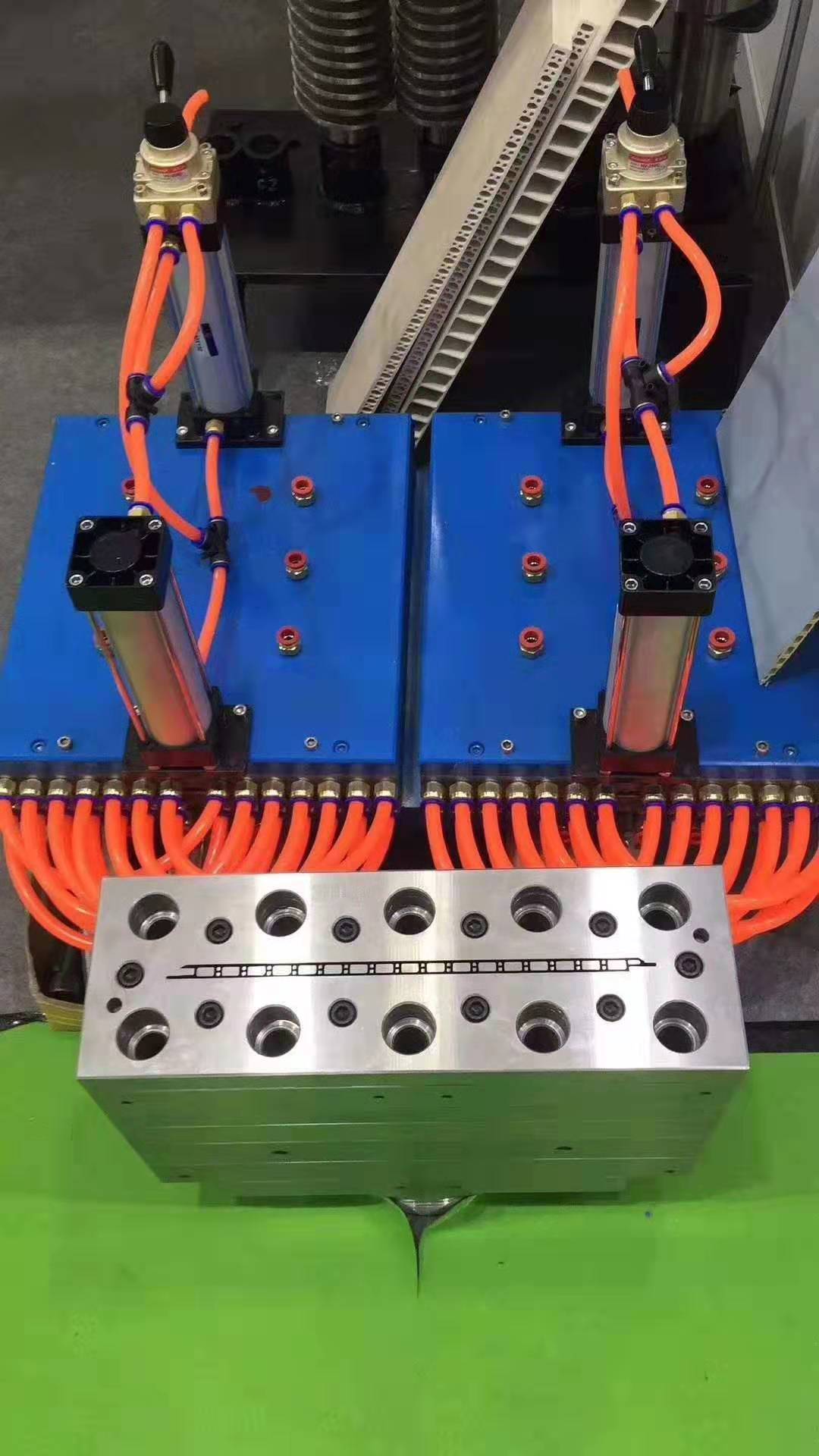

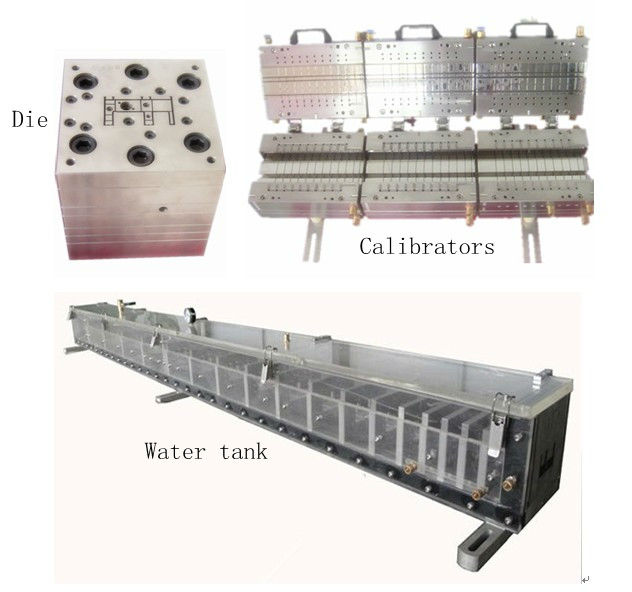

Mould composition | Die head, aluminum heating panels, calibrators and water tank |

Feature | High polished surface, stable discharging, soft-hard, surface layer, cladding |

Test | Mould will be tested to get the satisfy sample before delivery |

Sample | Sample will be arranged by express for customer approval |

Service | Provide complete set of formulation, technology and perfect after sale service |

Our extrusion mould advantages:

1.we are founded in 2010,.extend 11 years professional experennce gives us dominate position in extrusion moluld industry., quality and precision are the most import target of our company.our products enjoy an excellent reputation in plastic extrusion mould industry.

2.We owned a team of mature and experienced technicians,rich experiences workers from design, manufacture and debugging department.

3.We can make all kinds of moulds according to customer requirement.The mould can be extrusion profile, color co-extrusion, embossing co-extrusion, surface layer and so on.

4.Provide complete set of production process and technology transfer service .

5. Flow channel systematic design is based on theoretical calculation, practical conclusion, adopting reasonable compressing ratio and stain technology according to different formula and technique

DIE

1) Die design is based on flow simulations on our computer, flow analysis and experience, that leads to excellent flow characteristics.

2) High precision positioning pin design guarantees accurate plate assembly

Calibrator

uses high efficient vacuum device and cooling system design to guarantee great quality of finished products and smooth profile surface

Water/vacuum tank

a) Newly designed water/vacuum tanks supply vacuum and cooling water

b) High quality materials and unique design ensures high efficient cooling and proper seal to maintain constant water and vacuum supply in the tank

c) Self adjusting templates guarantee final sizing of profile

d) Tank material available: Plexiglas or fiberglass

e) High-sealing vacuum water tank of PVC window mould adopts floating setting design, able to adjust automatically

Moulds we made:

Fine quality after-sale service:

1.Our company has high level of technology,rich experiences in testing mould and good reputation service team.

2.Principles of service: First testing combined with tracking service

Orientation services linked with peripatetic service

Technical services united with training endorsement

3.Replying clients' problems in time ,and the technical can be arrived in three days.

4.One year warranty for the mould,and maintain for the whole life.

Product test results

NO. | Test Items | Technical Requirements | Units | Measured Value | Single Conclusion |

1 | Extrusion speed | 0.8-1.8 | m/min | 0.87 | conform |

2 | Yield | >98 | % | 99 | conform |

3 | Thickness deviation | <1.2 | mm | 0.24 | conform |

4 | Water absorption | ≤3.0 | % | 1.0 | conform |

5 | Density | ≥0.85 | g/ cm³ | 1.38 | conform |

6 | Tightness | No leakage | / | conform |

Product line:

Mould composition:

Our export mould :

If you are interested in our moulds, please feel free to contact with us and show us your sample picture or drawings.We will do our best to provide you with competitive price and professional service!